Multilink Engineering Services (MES) proudly offers the Specialized Carbide Drilling System—a mechanical cleaning solution designed to tackle the toughest deposits like coke, concrete, and hardened scale that are impossible to remove with traditional methods.

Why Choose Our Carbide Drilling System?

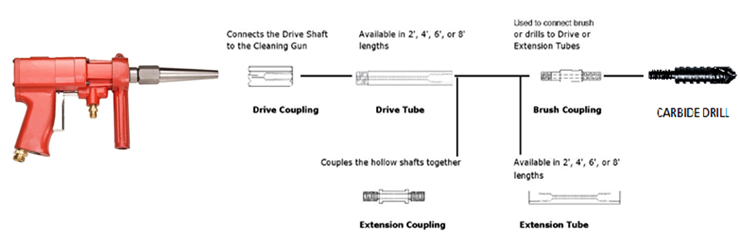

When tubes become fully choked and conventional cleaning fails, our system uses an air-driven motor combined with continuous water flow to drill through the hardest buildup safely and effectively. The water keeps the drill bit cool and flushes out loosened debris, ensuring smooth operation even in tight spaces.

When tubes become fully choked and conventional cleaning fails, our system uses an air-driven motor combined with continuous water flow to drill through the hardest buildup safely and effectively. The water keeps the drill bit cool and flushes out loosened debris, ensuring smooth operation even in tight spaces.

Key Features

Precision Carbide Drill Bits

Self-guided and sized exactly to the tube ID, eliminating risk of damage or wall loss.

Effective on Severe Scale

Removes extremely hard deposits that hydro-jetting cannot handle

Safe for Metallurgy

No adverse effects on tube or shell materials—preserving heat transfer integrity

Compact and Mobile

Designed to operate efficiently in restricted or hard-to-access areas

Environmentally Responsible

Chemical-free process that uses water responsibly

Applications

Perfect for cleaning internal tubes in:

- Heat Exchangers

- Boilers

- Condensers

- Evaporators

MES’s Specialized Carbide Drilling System delivers unmatched cleaning power for the most challenging tube fouling problems, ensuring your equipment operates safely and efficiently.

Contact us today to discuss how our system can restore your fully choked tubes with precision and care.