Smart Industrial Solutions

Automation, Intelligence & Engineering

TALK WITH US!

+92 51 4499251

Automation, Intelligence & Engineering

We deliver customized Open Architecture Smart Industrial Solutions designed to enhance operational efficiency, reliability, and insight across your industrial processes. Through our advanced capabilities in data acquisition, industrial automation, and custom engineering, we empower businesses to harness real-time intelligence and automation for smarter, safer, and more productive operations.

Our collaborative ecosystem, strengthened by partnerships with Codexter Labs and PAAIE, enables us to integrate the latest innovations – from AI-powered predictive maintenance to bespoke IoT and embedded systems – tailored precisely to your unique challenges.

Whether it’s deploying robust real-time monitoring systems, automating complex manufacturing workflows, or engineering custom IoT solutions, Multilink Engineering Services is your trusted partner in transforming industrial operations with smart, future-ready technologies.

We deploy robust data loggers to capture critical process variables, ensuring traceability, compliance, and informed decision-making during operations.

Real-time monitoring both on-site (edge) and remotely (cloud), enabling 24/7 visibility and faster response during maintainence shutdowns.

Through AI/ML-powered analytics, we identify issues before failure, helping clients reduce unplanned downtime and optimize maintenance schedules.

Tailor-made data acquisition software and intuitive dashboards to provide operators with actionable insights and real-time alerts for smarter operations.

Integrates automated machinery, robotics, and control systems to streamline production processes, ensuring consistency, speed, and reducing human error.

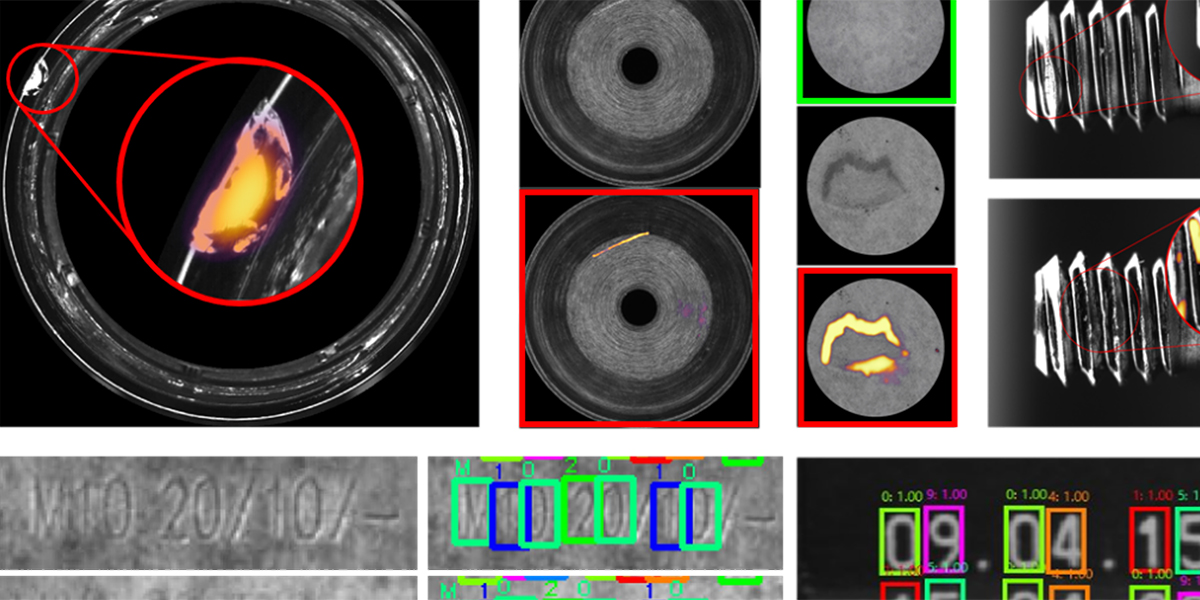

Leverages automated systems and AI to monitor, detect, and correct product quality issues in real-time, ensuring high standards and reducing defects.

Automates repetitive, rule-based tasks using software robots, increasing efficiency, accuracy, and freeing human workers for more complex activities.

Utilizes advanced cameras and image processing software to enable machines to “see” and analyze their environment, automating inspection, measurement, and quality control processes.