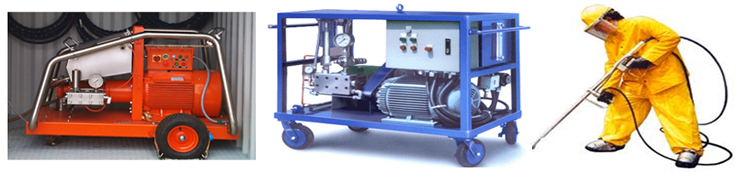

We have a rich heritage of providing high-pressure water jetting and hydrolancing services designed for powerful, precise, and environmentally safe cleaning of industrial equipment. Our techniques provide a highly effective solution for removing scale, rust, coatings, and other tough deposits without the use of harsh chemicals or solvents.

High-Pressure Water Jetting

External Surface Polishing & Contaminant Removal

Our high-pressure water jetting method is ideal for cleaning the external surfaces of industrial assets, offering a safe and cost-effective alternative to chemical cleaning. Using controlled, high-velocity water jets, we remove corrosion, coatings, contaminants, and residue from:

- Heat exchangers, condensers, and coolers

- Tanks, vessels, and reactors

- Storage areas and contaminated flooring

- Production equipment and pipelines

- Structural steelwork and machine parks

- Rust, paint, and scale from surfaces

- Shell exteriors and general surface polishing

This method ensures high levels of cleanliness with minimal environmental impact, improving equipment performance and product integrity while reducing waste disposal and chemical handling concerns.

Hydrolancing

Internal Tube Cleaning with Precision and Safety

For internal tube cleaning, MES uses its specialized Flex Lancing technique – a highly effective, non-invasive method that uses high-pressure water jets to remove scale, blockages, and fouling from deep within tubing systems. This method is safe for all types of tube metallurgy and does not involve chemicals that may harm equipment or the environment.

We clean both straight and U-shaped tubes with precision, including:

- Shell & Tube Heat Exchangers

- Chillers and condensers

- Evaporators

- Air fin coolers

Flex lancing provides thorough de-choking and deposit removal, improving heat transfer efficiency and extending the lifespan of your equipment. The method is adaptable, clean, and supports recycling through closed-loop systems, making it ideal for modern, sustainability-focused facilities.

Key Benefits

- Proven expertise across oil & gas, power, petrochemical, and manufacturing sectors

- Environmentally responsible methods – no hazardous by-products

- No damage to base materials – protects equipment integrity

- Closed-loop systems available for water recycling

- Safe for operators, plants, and the surrounding environment