Chemical Cleaning of Industrial Boilers

Multilink Engineering Services provide a range of technical support services for new and existing plants, industrial boilers (which may be coal, oil, gas or waste-gas fired). The company has many years of experience in plant improvements aimed at enhancing plant availability, reliability, capacity and efficiency.

Multilink Engineering Services provide a range of technical support services for new and existing plants, industrial boilers (which may be coal, oil, gas or waste-gas fired). The company has many years of experience in plant improvements aimed at enhancing plant availability, reliability, capacity and efficiency.

Each Job is Unique

Our engineers develop a comprehensive plan for each job that defines chemical mixtures, equipment, staffing, ongoing monitoring, and testing.

Chemical Cleaning Expertise

-

Oxygen Systems

-

Utility Boiler Cleaning

-

Evaporators

-

Heat Exchangers

-

Digesters

-

Cooling Water Systems

-

Tank and Reactors Cleaning

-

Power Boiler Chemical Cleaning

-

Recovery Boiler Chemical Cleaning

-

Pipe Cleaning: Scale and Product

-

Pre-Operational Cleaning and Flushing

-

Degreasing, Pickling, and Passivation

-

Ultra Clean Applications – Medical, Pharmaceutical, Food

Boiler Chemical Cleaning

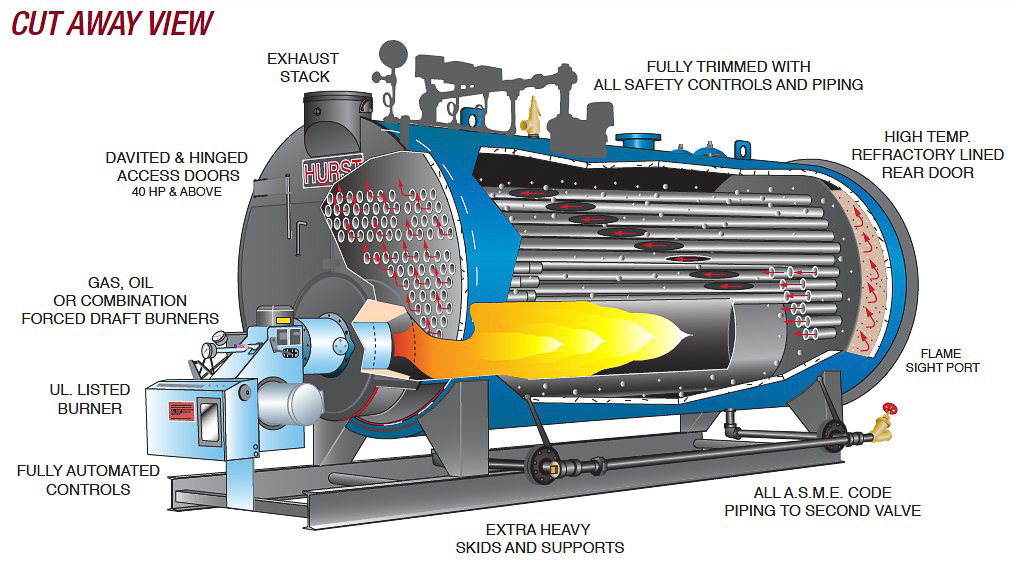

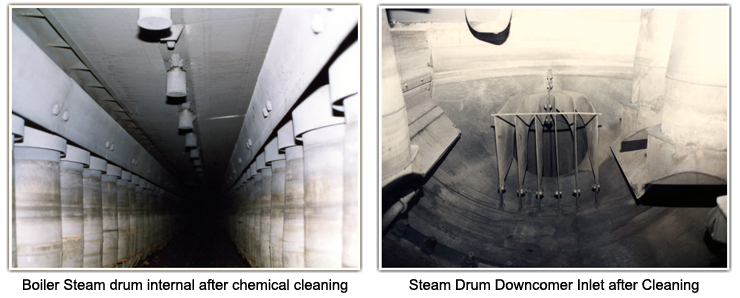

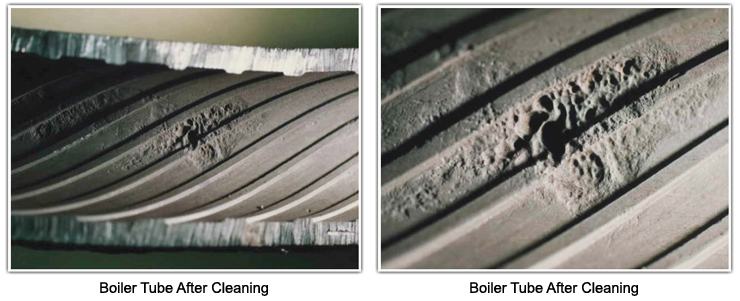

Chemical cleaning has been considered a necessary part of boiler maintenance for many years. The objective of a chemical cleaning is to safely remove all the deposits from the inside of the boiler tubes. In low-pressure boilers, chemical cleaning typically removes calcium carbonate and other hard adherent scales. In higher-pressure boilers, the major deposit removed is magnetite and some copper.

Chemical cleaning can improve the boiler heat rate and reduce the number of tube failures. It typically improves the stability of boiler chemistry.

Chemical cleaning can improve the boiler heat rate and reduce the number of tube failures. It typically improves the stability of boiler chemistry.

Pre-Commissioning Cleaning

Deposits originating both from fabrication should be considered potential problem. All pressure parts of a steam generator may be subjected to heat treatment of some sort during fabrication or erection – during forming operations, stress relief, welding or bending. Whenever carbon low alloy steels are subjected to high temperatures in the presence of air, oxidation occurs, the oxides produced is known as mill scale. Chemical cleaning are done for removal of these foreign materials and keeping the pressure part internals clean.

Deposits originating both from fabrication should be considered potential problem. All pressure parts of a steam generator may be subjected to heat treatment of some sort during fabrication or erection – during forming operations, stress relief, welding or bending. Whenever carbon low alloy steels are subjected to high temperatures in the presence of air, oxidation occurs, the oxides produced is known as mill scale. Chemical cleaning are done for removal of these foreign materials and keeping the pressure part internals clean.

We have a joint venture with Chemical Cleaning Consultants Ltd, UK. that offers independent advice and consultancy service on a worldwide basis in the following cleaning and associated services:-

-

Chemical Cleaning (Precommission & In Service Cleaning)

-

Chemical Decontamination

-

Hydrotesting to ASME Codes

-

Air & Steam Blowing Service

-

Pigging/Drying of Systems

-

Effluent Treatment & Storage

The businesses covered include power generation, petrochemical, paper, chemical & pharmaceutical industries.

The businesses covered include power generation, petrochemical, paper, chemical & pharmaceutical industries.

List of Chemical Cleaning of Power Station Boilers CCCL have been involved in.

United Kingdom – ConventionalDrax (6 x 660MW)Eggborough (4 x 500MW)Ferrybridge (4 x 500MW)West Burton (4 x 500MW)Cottam (4 x 500MW)Higher Marnham (5 x 200MW)Fiddlers Ferry (4 x 500MW)AgecroftDidcot (4 x 500MW)BlythCockenzie (4 x 350MW)Longannet (4 x 600MW)Hams Hall BDrakelow B & CWillington BRugeley APembroke (4 x 500MW)Ince B (2 x 500MW)Ironbridge (2 x 500MW)Ballylumford (6 x 350MW)Kilroot (2 x 350MW)Belfast WestCoolkeraghEireRingendPoolbegTarbetGreat IslandAghadaSouth AfricaDuva (6 x 600MW)Matla (6 x 600MW)Kriel (4 x 600MW)TaiwanHo Ping (2 x 660MW)MalyasiaTuanki Jaffa | United Kingdom HRSG’sRocksavageLittle BarfordConnah’s QuayDeesideShottonDamhead CreakRoosecoatCorytonSutton BridgeDidcotStaythorpePembrokeGreat YarmouthBallylumfordEireRingsendQatarRas GirtasSaudi ArabiaQurayyah AQurayyah BZimbabweBulawayoHong KongCastle PeakBlack PointSudanKhartoum NorthLibyaLISCO, Misurata |

Stephen Wynne

Stephen Wynne